Our malting plants

Fit for international competition

Fit for international competition

Steeping, germinating, kilning – each stage of malting places high demands on your skill and on the technical equipment. If problems occur with water supply, aeration, separation of batches, or transport, this has a short-term effect on the quality of the malts and a long-term negative impact on sales. As if that were not enough, price increases in the energy sector and the high demands on resource-saving production are proving to be additional problems in the malting plant.

Instead of tackling each problem individually, it is advisable to install viable and cost-saving overall solutions. Highly automated malting plants from Lausmann ensure that you can plan and control individual processes smartly. From setting the time intervals for dry and wet steeping, to efficient aeration and turning of the individual batches, to gentle drying and onward transport, all processes can be flexibly regulated with little personnel input.

Malting plants

We at LAUSMANN have specialized in malt. Technically and economically produced malt, which, in its harmony of taste, far surpasses the quality of a barn malt. Our core competence are malting plants with an annual demand of up to 100 tons per day, which attach importance to a controllable malt quality as well as flexibility in the daily production.

For decades, we have been designing and implementing malting plants that stand for quality Made in Germany worldwide. In addition to proven components in conveying and storage technology, we use our own developments in our plants, which make LAUSMANN malting plants unique.

We build our malting plants, depending on the requirements, with flat bottom diverter or hopper diverter and in germination we work according to the LAUSMANN germination box system (DBP) and according to the SALADIN principle .

Our scope of supply includes: – Silo plants – diverter – germination – kiln

and all transport systems tangential to our plants

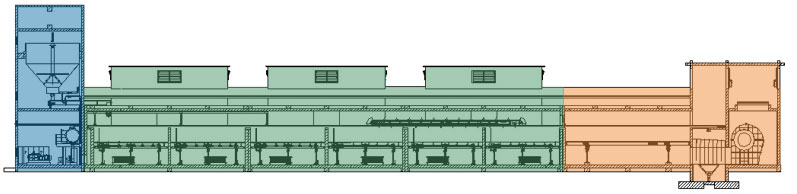

The Lausmann transfer box malting system with connection kiln (DBP)

LAUSMANN transfer box malting system (DBP)

The LAUSMANN transfer box malting system includes:

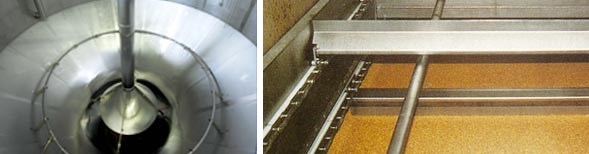

The complete steeping house. Depending on the requirements, we use flat-bottom steeping for large batch capacities and particularly uniform aeration or traditional hopper steeping. Of course, the steeping process is fully automated in both systems.

The germination boxes in the LAUSMANN system consist of several germination boxes lined up in a row, each of which contains a day batch and is loaded and unloaded by a turning trolley with rotating turning shovels.

The advantage: Each germination box contains a day batch and is absolutely separated from the adjacent germination box. This ensures not only better hygiene but also individual treatment of the individual batches, the prerequisite for optimum germination according to individual recipes.

The connecting kiln, which is separated by a gate and is also fed by the turning trolley, eliminates the need for additional transport equipment.

The entire system is designed for the gentlest possible treatment of the germinated material and the possibility of individual treatment of each daily batch.

The steeping

The start for optimum malt quality:

For controlled water absorption of the grain, we use two steeping systems, funnel steeping or flat-bed steeping, depending on the requirements. Both systems focus on gentle treatment of the steeping material, intensive steeping, and uniform germination. The transport

of the steeping material to the germination line is gentle on the product – the prerequisite for top malt quality.

The last water addition in the steeping plant can be used for remoistening in the germination line. in the germination line. The steeping process is controlled fully automatically. In case of failure of the process control manual operation is possible at any time.

The germination

Two systems for optimum germination

Germination in LAUSMANN malting plants is carried out according to the LAUSMANN system or in round or square germination boxes according to the SALADIN system. Both systems have been in use worldwide for years and feature optimum, individually controllable aeration and waste heat management.

The loosening, turning and rearrangement of the germination material is carried out gently and automatically as is typical for the system. Due to different sizes and shapes, these systems can be individually adapted to the respective performance requirements and are future-proof and expandable at any time.

Kiln

System-integrated and energy-saving

In the LAUSMANN box malting system, the kiln is directly attached to the germination line. It is separated from the germination line by an insulated kiln gate so that the temperature difference between germination and kilning cannot adversely affect the germination process. The kiln is designed for one day’s batch. There, the finished malt is cleared in a very short time and the kiln is free for a new batch.

Loading and unloading corresponds to the function of the green malt conversion in the germination line. In kiln operation, only the green malt layer is kept lower to save energy.

The turning carriage ensures that the green malt layer is perfectly flat and loose, so that the drying process is absolutely uniform.

For separate kilns, round or square, loading and unloading is carried out by means of a height-adjustable loading and unloading machine. The loading and unloading process is individually adapted to the batch quantity via a PLC control system and runs fully automatically.

Silos

Already during the project planning with layout and design of the silo plant and the required equipment, we ensure future security and economic efficiency.

The best possible use of space, foresighted capacity planning, short conveying routes and expansion options with sorting systems, cleaning systems or dedusting systems are criteria that are already included in our consulting services.

Our experience lies in the construction of complex silo plants for malting plants, breweries, concentrated feed plants and warehouses. We work closely with architects and structural engineers to realize the best possible solution.

Our service includes the complete project planning and design, the erection in conventional construction, prefabricated construction or as steel construction, and the complete individually adapted silo control.

Conveyors

As a specialist for malting and silo plants, the manufacture and assembly of conveying systems for a wide variety of requirements is one of our core competencies.

Due to our vertical range of manufacture in metal processing, the assembly is carried out completely in-house.

As drives we only use high-quality drives from leading manufacturers, so that a complete supply of spare parts is guaranteed worldwide for many years to come.

Plant engineering

As a specialist for malting plants, we lay the foundation for economic efficiency and longevity in the project planning and construction of our plants for malting plants, breweries, concentrated feed plants and warehouses. In close cooperation with architects and structural engineers, we develop functional concepts and realize the project economically and on schedule according to the latest control, conveying, sorting and cleaning technology.

Thanks to our flexible modular design, our plants can also be expanded to meet future requirements.

You receive from us from one source

- planning, manufacturing, assembly and commissioning of complete plants or single plants

- construction according to your wishes. Conventional, prefabricated construction or steel construction

- The complete control system incl. switchgear and programming

Due to our extensive in-house production, we are able to supply customized, individual malting and silo plants which correspond to the latest state of the art.

Ask us. We will find the best solution for your project.

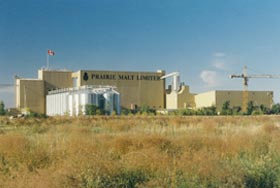

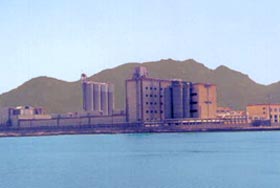

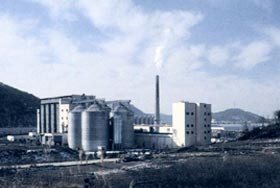

References

For decades we have been designing and building complete malting plants, individual components and modernizing old plants.

We would be pleased to inform you in detail about our possibilities.

Malzfabrik A Müller, Inkofen, Germany

Mich. Weyermann GmbH & Co. KG, Bamberg, Germany

Korea Equipment & Plant Corporation, Pyongyang, DPR Korea

Prairie Malt LTD, Biggar, Saskatchewan, Canada

Intermalta, S.A., San Adrian, Spain

Palatia Malz GmbH, Kreimbach-Kaulbach, Germany

China Jiangsu Suntory Foods Co. LTD, Haizhou Lianyungang Jiangsu, PR China

LYCOS – Trnava Malt House, Trnava, Slovakia

Oriental Brewery Co. LTD, Kwangju, Korea

Mianyang Malting Plant, Mianyang Hubei, PR China

Viking Malt, Lahti, Finland

Malting with system – naturally from Lausmann

The special Lausmann system is also designed for the highest quality in taste and grade and allows you to produce flexibly and automatically, depending on the grain, the quantities and the desired product, without the need for costly conversions.

Simply send us your order or inquiry by e-mail. Alternatively, call us so that we can clarify important parameters right away and prepare a personal offer for you.

Your advantages:

Optimal use of space

Fully automatic malting process

Gentle crop handling

Central control and regulation system

Low personnel requirements

Optimum energy efficiency

Planning, manufacturing, assembly and commissioning of complete plants

We will be glad to help you.

Simply send us your inquiry by e-mail. Or give us a call.

Peter Setz (Sales manager)